BusinessMind's Pluggable Jewelry Manufacturing Software Modules Deliver Simplicity, Flexibility, And Power

For jewelers who manufacture their own stock, BusinessMind offers a lot of flexibility and power over the build control processes. BusinessMind software for manufacturing jewelers aims to simplify complex functions and then stay out of the way so the creative process of crafting jewelry can keep the focus.

To keep things as simple as possible, it is important that the jewelry software's Bill Of Materials (BoM) features are as tailored to fit as possible. Since the BoM structure can vary so widely depending on the manufacturer's processes and the type of jewelry being crafted, the best way to get a tailored fit in the jewelry software's BoM functionality is through a pluggable custom BoM module. This is the approach used by BusinessMind. In this article we will explore some basic examples of what a custom manufacturing module might look like.

When BusinessMind software for jewelers is first installed, on the model screen, the area reserved for BoM controls will display with a message indicating that a customized BoM module tailored for your own manufacturing products, processes and requirements can be plugged in at your option.

The process of building a custom BoM module tailored to your business begins with a short conference call to help us understand your requirements. The length of time required, and the cost to create is directly related to the complexity and functionality needed. Once all the necessary information is gathered, an estimate will be provided to you for your approval.

Typically, we will ask you to share some examples of your existing BoM handling, whether it be in Excel, index cards, or other software. From this we can gather information as to what features your BoM module needs to provide for you. For example, typical handling of diamonds in production will require specifying attributes like mm size and shape. It will also require measuring count, weight, and cost per weight. From these, total build requirements a cost should be calculated. On screen data entry for basic needs might look like the following.

Example BoM control based on core attributes for managing diamonds.

If your manufacturing process deals mostly with diamonds of a specific set of attributes, something more tuned to those attributes can simplify entry and prevent data entry errors as in the example below. This type of tailored fit to your manufacturing process is only available through custom built modules as BusinessMind offers.

Example of BoM diamond management by shape and mm attributes which auto-calculate weight and cost.

Different types of jewelry and manufacturing processes can utilize in-house castings, findings from a specialized provider, forms from wire, forms from sheet metal, and many other variations of metal components. Below is a concept of what data entry for processing casting components might look like which includes, number of pieces, finished and casting weight, and casting labor.

Example of screen attributes for a typical casting BoM component.

Besides the wide variety of metal component types, you may be working with various types of metals. Perhaps you produce products in varying metals like silver, 18kt gold, or palladium. Perhaps many of your products combine multiple metals and can be produced in different combinations. In such cases your custom built BoM module may look something like the example below.

Example of a custom BoM control that can cost metal components by calculating weight in varying metals by specific gravity using the silver weight as a base, and, cost based on current market value.

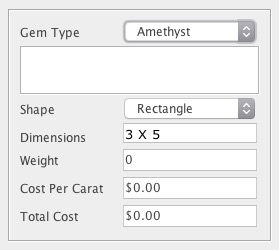

Your manufacturing process may not use diamonds at all, in which case your gem data entry would take on traits appropriate for the types of gems that you use. An example of what your custom BoM may provide for this is shown here.

Example for handling of multiple gem type individual stones in a BoM.

Other factors like labor and markups can be handled in a wide variety of ways and at any number of tiers in the process. The methods you specify will be incorporated into your custom BoM module.

Once completed, your custom BoM module is installed into your BusinessMind account. Your custom BoM will integrate seamlessly with existing BusinessMind jewelry manufacturing and fulfillment operations flow such as order management, JIT component stock maintenance, supplier order management, and workshop component usage and process tracking.

The completed customized BoM module integrates seamlessly into the application.

To recap, jewelry manufacturing can vary widely depending on the type of jewelry being manufactured and the processes of the manufacturer. A generalized jewelry manufacturing application will always result in software that is too complex, not flexible enough, or lacking in features. BusinessMind solves these issues with custom built BoM modules that plug into the software and integrate seamlessly.